Note: Originally posted by Peter Grabow. I re-posted to test Discourse out.

Hi All -

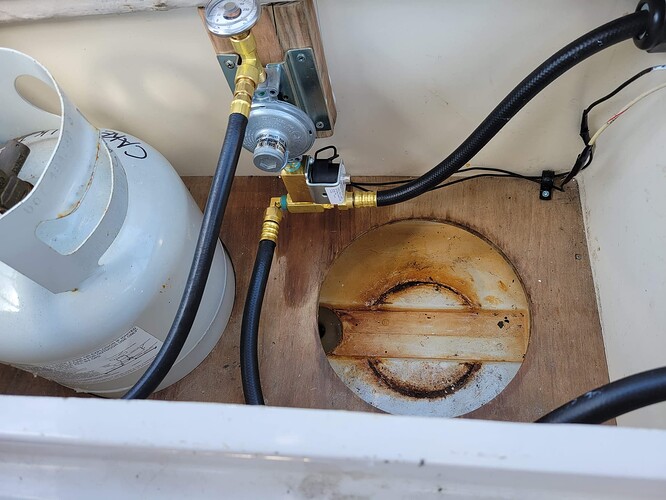

I completed the upgrade of the propane system a couple of weeks ago. I am happy to report that the new system passed two different leak tests (soapy water at every connection and the leak gauge test), I didn’t blow myself up, or anyone else for that matter! There is no smell of propane in the propane locker or anywhere else in the boat. The propane ‘sniffer’ indicates all is clear too.

The new lines posed a few challanges - I had to move my mid-ship watertank a couple of inches to be able to get the line from the stove into the bilge, and thought I thought I had figured out how to use the old hose to the on-demand water heater as a messenger for the new hose, the piece connect the old and new hoses pulled out of the old hose before I was able to pull the new hose thru and it was behind the cabinetry and raised floor piece under the galley sink - took 45 mins of playing around but I was finally able to reach it and pull it through.

The original set-up ‘T’-ed just outside the cabin in the engine copmartment - today’s regulations forbid this, so the new set-up ‘T’'s inside the propane locker.

The original set-up had the solenoid wires taped to the propane hose inside the propane locker. Outside of the propane locker they were zip-tied to the propane hose, along with the sternlight wiring and the bilge-blower hose.

I put the wiring and bilge blower hose into their own cable supports so they are separated from the propane hoses.

The now two propane hoses run in parallel to each other but fixed through their own cable/hose supports.

I drilled a separate hole in the propane box for the wires to enter/exit, and then caulked it closed with 3M 4200. The wires run through their own cable guides within the locker so they don’t get caught on anything.

I installed two Trident Marine Vapor Tight fittings, one for each hose, to maintain the vapor tight integrity of the propane locker (with the exception of the drain in the locker floor that leads straight overboard). I caulked the Vapor fittings from the outside of the propane locker with 3M 4200 as well.

I opted for a mounted regulator to make a cleaner installation. I did end up using a low-pressure solenoid, though there were some who suggested that the high pressure solenoids were of higher quality. I was not able to configure the system with available parts by using the high pressure solenoid, so I gave in and went with the low.

All NPT connections are properly taped with the yellow propane plumbers tape. In the US yellow is designated as the correct color for propane, though I beleive in Canada the correct color is different (possibly pink/red?). Flared connections were left un-taped as per regulations/instructions.

I also used rubber pipe insulation to protect each new hose from chafing at every point at which they pass thru a floor riser, cabinet edge, or where they could possibly rub against each other.

The new low-pressure, pilotlight-less Excel water heater works very well! Hot water is pretty much immediate and stays hot even when running the water slowly. The reconfiguration of the old Paloma vent/chimney (mentioned in a previous post) is working well with all heat going up and out of the boat.

So far, so good!

Some photos are attached.

Oh - and if anyone notices anything I did incorrectly, especially if it may result in a dangerous situation, please let me know!!

Peter Grabow

S/V CAKE WALK III

1987 30 Ultra 430

Jersey City, NJ